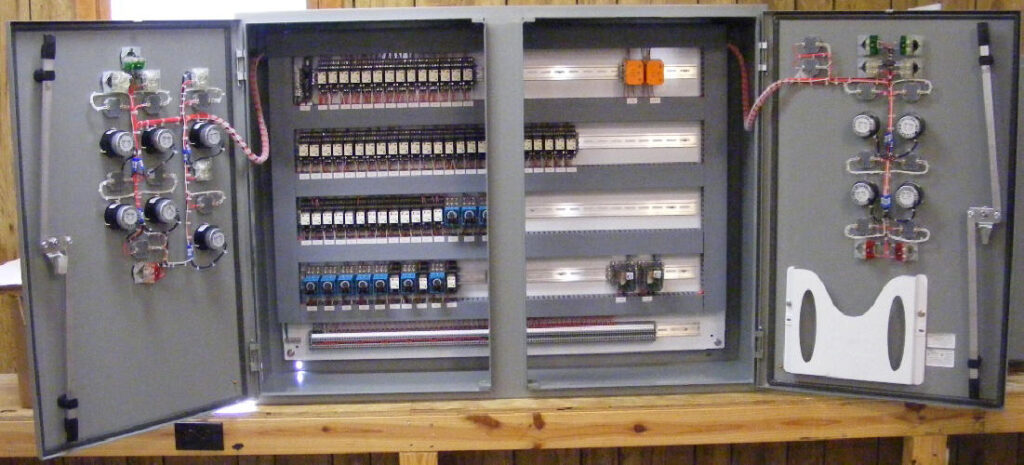

We are able to manufacture control panels to fit any need in the municipal market. Our custom panel design is not limited to individual control panels, but we offer complete system solutions. In addition, we offer the ability to upgrade/modify existing control systems, as well as complete system integration. Please contact us for more information or design assistance.

Our Custom Control Panels Texas

Quality and excellence must be included in the manufacture of electrical controls panels which serve the water and wastewater industry. Installations are often made under the worst possible conditions. But these are the installations on which the public depends in order to assure public health. It is a serious situation when a community has no water or when a failed sewage pump station causes sewage to back up into homes and businesses. When dependability is important, quality counts.

In an effort to provide reliable service, our control panels use tested and proven components and circuitry and can therefore be expected to perform dependably for years. In addition, the panels are designed for ease of service–a key factor in the small towns that are far from metropolitan parts sources.

Except for modules such as phase failure relays and alternating relays, we do not use printed circuit wiring. We only use domestic, NEMA-rated motor starters, primarily manufactured by Square D. We do not use IEC-rated components for our standard panels because IEC components are not up to our standard of quality. IEC-rated components are not rated with the reserve capacity that keeps NEMA-rated components running for years longer.

Panels built by Mercer Controls include many additional features to further enhance quality and dependability. Our panels use control relays with contacts that are rated for 10 amperes. The relays always include monitor lamps to visually aid in servicing. Wiring is routed through Panduit. All float switch circuitry is operated at 24 volts, which removes electrical shock hazards from lift station wet wells. Inner doors are painted with automotive enamel for a pleasing appearance. All control wires are numbered, and our documentation and labeling are superior.

At Mercer Controls, we think about your needs and we make every effort to meet them with a quality product!

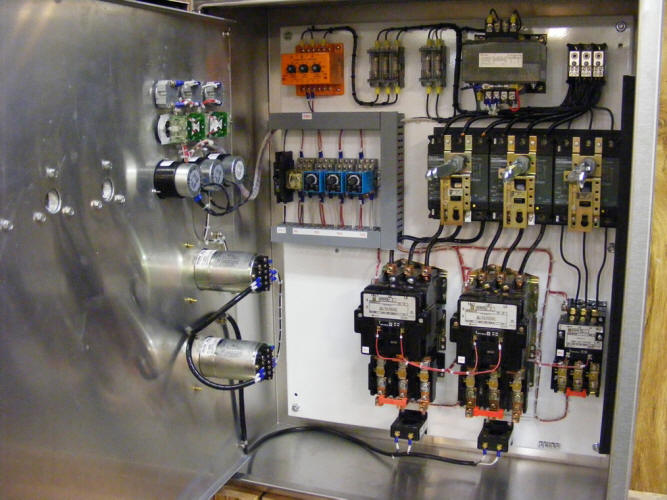

Motor Control Center

Our motor controllers will have differing features and complexity depending on the task that the motor will be performing. Simplest case may be a switch that manually operates or may be a relay or contactor connecting to some form of sensor to automatically start and stop the motor. This switch may have several positions to select different connections of the motor. This may allow reduced-voltage starting of the motor, reversing control or selection of multiple speeds. More complex motor controllers may be used to accurately control the speed and torque of the connected motor (or motors).

Instrumentation Control Panel

Our Instrumentation Control Panels are designed to protect sensitive instrumentation from the harsh environments found in water and waste water treatment plants. These panels also include components for lightning protection as well as heaters to provide freeze protection.

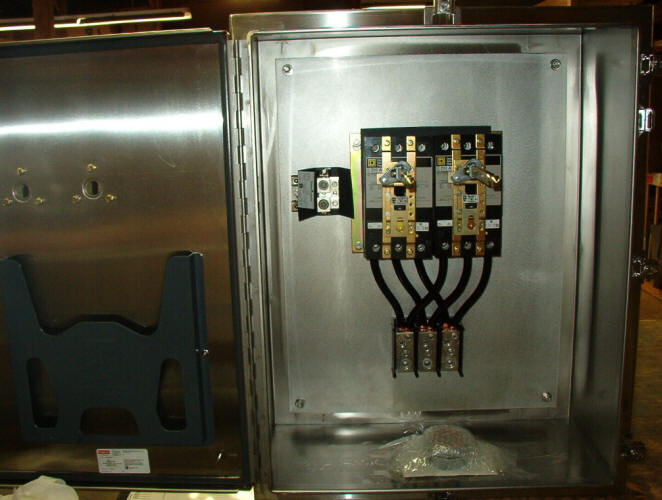

Walking Beam Disconnect

Our Walking Beam Disconnect Panels are designed to provide a method to manually switch from utility to generator power. These panels provide a cost effective alternative to a manual transfer switch and can be custom manufactured with generator power cord quick connects.

Switch Gear Control Panel

Our Switch Gear Control Panels can provide an alternative to a Motor Control Center (MCC) for certain applications and are typically much more effective. Switch Gear Control Panels are only available as a custom design.

Blower Control Panel

Our Blower Control Panels utilize Variable Frequency Drives to control the operation of blowers. These control panels can be designed to include the use of Dissolved Oxygen Meters to adjust the speed of the blowers to maintain a specific Dissolved Oxygen level set by the operator. These panels are available as custom deigns to fit your specific needs

Auto-Sensory Control Panel

Our Auto-Sensory Control Panels provide a method of controlling the operation of water treatment plants without the use of a programmable logic controllers. These control panels utilize comparators and 4-20mA signals to start and stop the pumps. We can customize these control panels to fit your specific operation needs.